Aluminum Rod Manufacturer/Supplier

About Zhenhan

Guangdong Zhenhan Special Light Alloy Co., Ltd.

Established in 2011, Guangdong Zhenhan Special Light Alloy Co., Ltd. is an innovative technology manufacturer specializing in high-end alloys, and is committed to becoming a technology pioneer in the field of metal raw material manufacturing through technological innovation. Zhenhan Alloy has a modernized production base for metal raw materials, covering an area of 15,000 square meters, with multiple and complete sets of advanced production lines; It has obtained the ISO quality management system 9001:2015, 16949 certification and won many awards.

At Zhenhan, we are proud to offer a wide range of aluminum bar products to meet a variety of industrial needs. With such a rich product range, we are able to provide solutions for applications such as transportation, electrical engineering and high-performance industries.

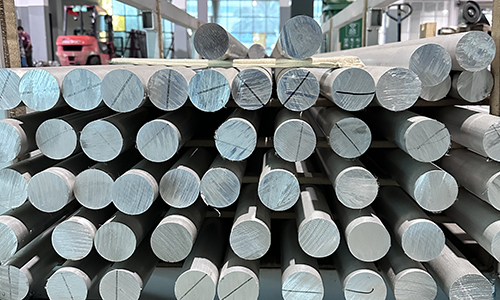

Aluminum Extruded Bar Rod is one of Zhanhan Aluminum’s high-quality products, produced using advanced extrusion machines with capacities ranging from 550 to 2200 tons, all controlled by a PLC system for precision and consistency. Zhenhan can produce rods from various alloys, including 2024, 2014, 2017A, 2618, 5083, 6061, 7075, and more. These rods are widely used in industries such as aerospace, automotive, and construction, offering excellent strength, durability, and corrosion resistance for high-performance applications.

6061 t4 t6 t651 extruded aluminum bar

6063 t4 t6 t651 extruded aluminum bar

6082 t4 t6 t651 extruded aluminum bar

7075 t73 t73511 t6511 extruded bar

7150 t77511 extruded bar

2024 T3 T4 T351 T3511 T8511 extruded aluminum bar

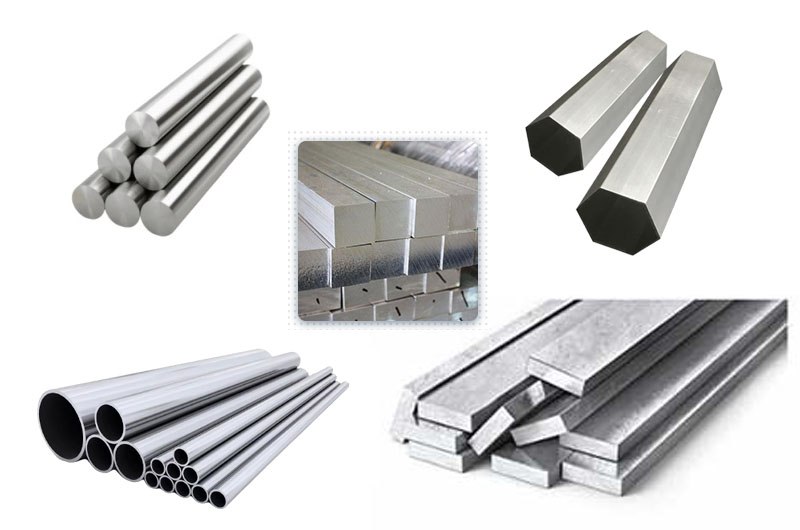

Aluminum round bars can be obtained by extrusion and drawing, and circular aluminum bars are the most widely used products; further process such as sawing, polishing can be provided.

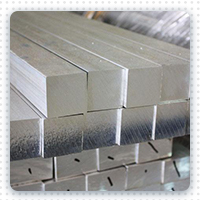

Extruded aluminum bar with a 90 degree acute angle, which requires higher extrusion performance and is often used in the power industry after certain processing.

Light weight, high stability, and corrosion resistance, and is widely used in various industries such as buildings, manufacturing, and parts processing.

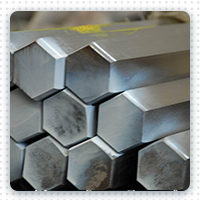

Featuring a hexagonal cross-section, this bar is ideal for applications requiring high strength and precision, such as machinery parts and automotive components.

It can be strengthened by heat treatment, has moderate plasticity in annealing, just quenching and hot state, has good spot welding performance, and tends to form intergranular cracks when welding by gas welding, argon arc welding, etc.

The tolerance of Zhenhan cold-formed aluminum bars is less than -0.03 mm, the straightness is within 0.3 mm/m, and the roundness is 0.01 mm. The material consistency is excellent, and the ends are chamfered to prevent material jamming. These aluminum bars are very suitable for applications with medium tolerance and diameter requirements, especially for CNC machine tools with spindle speeds exceeding 5000 rpm.

Cold-Finished (CF) Aluminum Bars are produced using a cold drawing process, with repeated drawing to achieve the desired diameter. This multiple-drawing technique ensures an exceptionally smooth surface and high precision.

Aluminum round bars can be obtained by extrusion and drawing, and circular aluminum bars are the most widely used products; further process such as sawing, polishing can be provided.

Extruded aluminum bar with a 90 degree acute angle, which requires higher extrusion performance and is often used in the power industry after certain processing.

Aluminum round bars can be obtained by extrusion and drawing, and circular aluminum bars are the most widely used products; further process such as sawing, polishing can be provided.

Extruded aluminum bar with a 90 degree acute angle, which requires higher extrusion performance and is often used in the power industry after certain processing.

Aluminum round bars can be obtained by extrusion and drawing, and circular aluminum bars are the most widely used products; further process such as sawing, polishing can be provided.

Extruded aluminum bar with a 90 degree acute angle, which requires higher extrusion performance and is often used in the power industry after certain processing.

Aluminum round bars can be obtained by extrusion and drawing, and circular aluminum bars are the most widely used products; further process such as sawing, polishing can be provided.

Extruded aluminum bar with a 90 degree acute angle, which requires higher extrusion performance and is often used in the power industry after certain processing.

Zhenhan precision ground aluminum rods feature a diameter tolerance of less than -0.02mm, straightness below 0.2mm/m, and true roundness of 0.005mm. The material exhibits excellent consistency, and the double-ended chamfering ensures smooth machining without material jamming. These rods are particularly suitable for applications with strict tolerance and diameter size requirements, especially in the utilization of Swiss-type CNC machines with spindle speeds exceeding 8000.

The organizational structure of Zhanhan forged aluminum bar is relatively dense and less prone to internal defects; widely used for processing components with high strength requirements and high wear resistance. Zhanhan aluminum forged rod with a maximum diameter of 650mm.

Hot selling alloy: 2A01 2A02 2A10 2A11 2A12 3A21 3003 3004 3005 5A02 5A03 5A05 5B05 5A06 5050 5052 5056 5086 6A02 61016005 6063 6061 6082 7A04

Zhanhan supplies large diameter bars, aluminum billets, and cast bars with flexible shapes and sizes, supporting diameters up to 1350mm. These products are ideal for applications requiring low density, large cross-sections, or custom geometries. Widely used in aerospace, semiconductors, tire molds, and heavy-duty industrial parts, they demonstrate Zhanhan strong capabilities in large-scale aluminum processing.

With an aluminum content typically above 99%, these rods feature excellent corrosion resistance and electrical conductivity. However, their strength is relatively low, making them suitable for conductive materials and chemical equipment.

Aluminum≥99.5; with high plasticity, corrosion resistance, good conductivity; Applied in reflective panels, chemical industry containers…

Known for its high aluminum content (99.7%) and excellent conductivity, 1070 is ideal for electrical and chemical applications.

Renowned for its excellent corrosion resistance, workability, and high purity, 1100 is a versatile choice for chemical and decorative applications.

With an aluminum content typically above 99%, these rods feature excellent corrosion resistance and electrical conductivity. However, their strength is relatively low, making them suitable for conductive materials and chemical equipment.

High strength hard aluminum, has good spot-welding performance, and is used in high strength situations.

Hard aluminum alloy with good thermal strength. Used for heavy-duty aircraft, structural and suspension system components.

Good cutting performance, high strength and excellent fatigue strength. When temperature is above 125 ℃, its strength is higher than 7075.

Good process performance during casting and pressure processing (whether it is forging, extrusion or rolling).

Due to the presence of low-melting point phases Pb7Bi3 and Bi in the alloy, high-speed cutting and large feed rate can be used.

High-strength alloy with excellent corrosion resistance and heat tolerance, making it ideal for aerospace and high-temperature applications.

With an aluminum content typically above 99%, these rods feature excellent corrosion resistance and electrical conductivity. However, their strength is relatively low, making them suitable for conductive materials and chemical equipment.

corrosion-resistant, weldable, versatile for decoration, packaging, construction, transportation, aerospace…

Aluminum 4000 series bars, aluminum-silicon alloys, offer excellent wear resistance, low thermal expansion, and high corrosion resistance, ideal for high-temperature and automotive applications.

corrosion-resistant, weldable, versatile for decoration, packaging, construction, transportation, aerospace…

With an aluminum content typically above 99%, these rods feature excellent corrosion resistance and electrical conductivity. However, their strength is relatively low, making them suitable for conductive materials and chemical equipment.

High corrosion resistance, beautiful anodized surface; is a famous marine and military alloy.

Adding magnesium, it has good formability and corrosion resistance; the most widely used type of rust resistant aluminum bar.

Rust prevention, corrosion resistance, and high fatigue resistance. Used for low load parts that require high plasticity and good weldability.

Rust proof, high plasticity and good formability. Suitable for containers with high process plasticity requirements and good corrosion resistance.

Offer high strength, excellent corrosion resistance, and weldability, ideal for marine and transportation applications.

With an aluminum content typically above 99%, these rods feature excellent corrosion resistance and electrical conductivity. However, their strength is relatively low, making them suitable for conductive materials and chemical equipment.

Medium strength, excellent processing and welding performance. The material is dense and flawless, making it easy to polish, and oxidize.

Excellent processing performance, corrosion resistance and anodizing effect; Widely used in profiles for building, fences, etc.

Can be strengthened by heat treatment; good formability, weldability, machinability, and corrosion resistance. Mainly used in mechanical structures.

Fatigue resistance, corrosion resistance, excellent high-gloss anodizing, widely used in 3C smart wearable electronic products, automotive parts, etc.

Excellent plasticity, processing performance, and fatigue resistance, widely used in the manufacture of mailboxes, oil pipes, ship sheet metal parts and other components

Due to its advantages such as light weight, high strength, good thermal conductivity and electrical conductivity, easy processing and corrosion resistance, it is widely used in aerospace, transportation, electronics and electrical appliances and other fields.

With an aluminum content typically above 99%, these rods feature excellent corrosion resistance and electrical conductivity. However, their strength is relatively low, making them suitable for conductive materials and chemical equipment.

Ultra hard aluminum, strength is high and far superior to soft steel. It is the preferred choice for aerospace and other high-strength industries.

Ultra high strength, high yield ratio, and high specific strength; becoming one of the most important structural materials in aerospace field.

Ultra high strength, high yield ratio, and high specific strength; becoming one of the most important structural materials in aerospace field.

Ultra hard aluminum, strength is high and far superior to soft steel. It is the preferred choice for aerospace and other high-strength industries.

Medium strength, good welding performance, excellent corrosion resistance, widely used in medical equipment parts, aviation parts, automotive structural parts, etc.

High strength and excellent welding performance, can be strengthened by heat treatment, often used to manufacture welded structures that require both high strength and high fracture toughness

Zhenhan offers a comprehensive range of aluminum bar customization services to meet the diverse needs of various industries. Our services include, but are not limited to, the following:

| Alloy | Shape | Diameter mm | Temper |

|---|---|---|---|

| 1050 | Round | Diameter:3-350 | O, H112 |

| Square | Side length: 6-160 | ||

| Rectangle | Thickness:1-160 Width: 6-570 | ||

| Hexagon | Width:6-80 | ||

| Aluminum Profile | Customize | ||

| 1060 | Round | Diameter:3-350 | O, H112 |

| Square | Side length:6-160 | ||

| Rectangle | Thickness:1-160 Width: 6-570 | ||

| Hexagon | Width:6-80 | ||

| Aluminum Profile | Customize | ||

| 2A12 | Round | Diameter:3-350 | T3 T351 T4 T451 T6 T651 T6511 T7351 |

| Square | Side length:6-160 | ||

| Rectangle | Thickness:1-160 Width: 6-570 | ||

| Hexagon | Width:6-80 | ||

| Aluminum Profile | Customize | ||

| 2A14 | Round | Diameter:3-350 | T3 T351 T4 T451 T6 T651 T6511 T7351 |

| Square | Side length:6-160 | ||

| Rectangle | Thickness:1-160 Width: 6-570 | ||

| Hexagon | Width:6-80 | ||

| Aluminum Profile | Customize | ||

| 2014 | Round | Diameter:3-350 | T3 351 T4 T451 T6 T651 T6511 T7351 |

| Square | Side length:6-160 | ||

| Rectangle | Thickness:1-160 Width: 6-570 | ||

| Hexagon | Width:6-80 | ||

| Aluminum Profile | Customize | ||

| 5052 | Round | Diameter:3-350 | O F H12 H14 H22 H24 H32 H34 H38 H111 H112 |

| Square | Side length:6-160 | ||

| Rectangle | Thickness:1-160 Width: 6-570 | ||

| Hexagon | Width:6-80 | ||

| Aluminum Profile | Customize | ||

| 5083 | Round | Diameter:3-350 | T3 T351 T4 T451 T6 T651 T6511 T7351 |

| Square | Side length:6-160 | ||

| Rectangle | Thickness:1-160 Width: 6-570 | ||

| Hexagon | Width:6-80 | ||

| Aluminum Profile | Customize |

| 6061 | Round | Diameter:3-350 | T3 T351 T4 T451 T6 T651 T6511 T7351 |

| Square | Side length:6-160 | ||

| Rectangle | Thickness:1-160 Width: 6-570 | ||

| Hexagon | Width:6-80 | ||

| Aluminum Profile | Customize | ||

| 6063 | Round | Diameter:3-350 | T3 T351 T4 T451 T6 T651 T6511 T7351 |

| Square | Side length:6-160 | ||

| Rectangle | Thickness:1-160 Width: 6-570 | ||

| Hexagon | Width:6-80 | ||

| Aluminum Profile | Customize | ||

| 6082 | Round | Diameter:3-350 | T3 T351 T4 T451 T6 T651 T6511 T7351 |

| Square | Side length:6-160 | ||

| Rectangle | Thickness:1-160 Width: 6-570 | ||

| Hexagon | Width:6-80 | ||

| Aluminum Profile | Customize | ||

| 7075 | Round | Diameter:3-560 | T3 T351 T4 T451 T6 T651 T6511 T7351 |

| Square | Side length:6-160 | ||

| Rectangle | Thickness:1-160 Width: 6-570 | ||

| Hexagon | Width:6-80 | ||

| Aluminum Profile | Customize |

1. Size Customization:Aluminum bars can be customized in length, diameter, and tolerance according to customer requirements. We ensure high-precision products that meet strict dimensional standards.

2. Alloy Composition Customization:Tailor the alloy composition based on specific application requirements. We offer aluminum bars in all series from 1xxx to 7xxx, meeting demands for different strength, corrosion resistance, and machinability levels.

3.Shape Customization: Provide various shapes, including round bars, square bars, hex bars, T-bars, Z-bars, L-bars, and more, to suit different application scenarios.

4. Heat Treatment:Services Provide heat treatment processes, such as quenching and aging, to enhance the mechanical properties and durability of aluminum bars based on application requirements.

5. Cutting Services:Perform precise cutting to customer-specified sizes or shapes, ensuring smooth, burr-free cutting surfaces suitable for precision machining or direct use.

6. Small Batch Customization:Support on-demand production for special projects or small-batch requirements, ensuring flexibility and cost-effectiveness.

7. Packaging and Logistics:Offer professional packaging services to ensure the safety of products during transportation, with global logistics support for prompt delivery to meet customer demands.

Whether it’s for complex technical requirements or personalized designs, Zhenhan provides high-quality aluminum bar customization solutions.

Do You Have Needs? We'd Love To Help You!

Menu

Products

Contact Us

- huangyuanxiang@zhenhanhj.com

- +86 15013666806

- +86 0755-88898853

- Guangdong Zhenhan Special Light Alloy Co., Ltd

- Building 11, No. 198, Zhenxing Avenue, Xiegang Town, Dongguan City, Guangdong Province, China

Copyright © Guangdong Zhenhan Special Light Alloy Co., Ltd. All rights reserved.